IPE RAILING SPECIFICATIONS

Ipe decking: dimensions and specifications. Deciphering the terms

The least you need to know: When people refer to “board feet,” they often actually mean “linear feet,” with around 90% of individuals using the term in this context. While “board feet” traditionally quantifies lumber volume, the widespread use of “linear feet” for specifying length reflects a common understanding in woodworking and construction.

When it is used: Most orders in the Ipe world are in Linear Feet

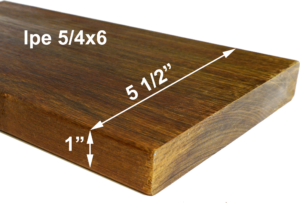

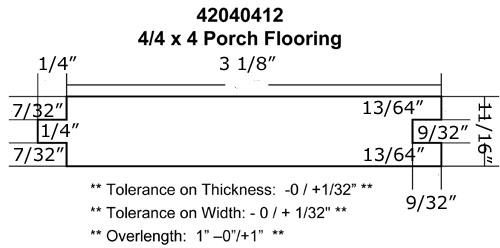

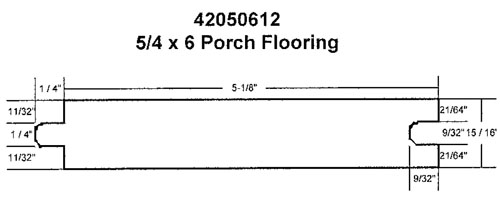

Nominal sizes in Ipe, like 1×6, are dimensions used for communication and marketing but may differ from actual measurements after processing. Rough sizes represent the true dimensions of the wood before planing or surfacing. For example, a nominal ¾” x 5 ½” board may have a rough size of 1 inch thick by 6 inches wide. Understanding this distinction is crucial for accurate project planning, as rough sizes provide precise measurements while nominal sizes offer convenient references for consumers and industry professionals.

S4S E4E means “surfaced on four sides, eased on four edges.” This lumber is planed smooth on all four surfaces and has slightly rounded edges. The eased edges reduce sharpness, making it safer to handle and minimizing splintering. S4S E4E avoids ipe wood problems as S4S E4E Ipe lumber is ready for immediate use in various projects.

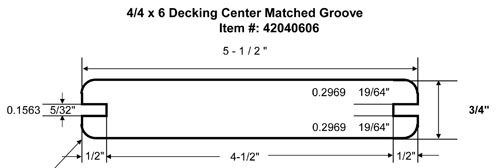

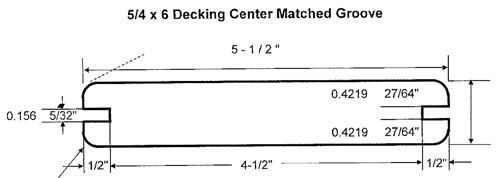

Grooved refers to Ipe decking boards machined with a groove cut into both sides to accommodate Ipe clips. These clips, including Ipe clip extreme clips, facilitate a smooth finish for your decking. By securely fastening the grooved boards with these clips, the decking surface remains free from visible screws or nails, ensuring a seamless and polished appearance. Grooved Ipe decking, paired with Ipe clips, offers a sleek and professional finish for outdoor projects.

Rough sawn lumber is wood that has been cut from a log using a sawmill but has not undergone any further processing or surfacing. It retains the natural texture and rough appearance from the sawing process, with uneven surfaces and saw marks. Rough sawn wood requires additional planing or sanding for smoothness.

When it is used: Rough Sawn is common in Apitong Truck Decking Market.

Cubic meters measure volume, beneficial for bulk purchases such as timber for construction. Board feet, primarily used in North America, quantify volume in the lumber industry. Linear feet, on the other hand, measure length along a straight line, commonly used for specifying dimensions in various woodworking and construction projects. While cubic meters offer a universal metric, board feet serve as a standard in the lumber trade, and linear feet provide a straightforward measurement for length. Understanding these distinctions helps ensure accurate purchasing and project planning, catering to different measurement needs across industries and regions.

When it is used: Cubic Meters are used in Bulk purchases and transfers between larger B2B.

| Marketing or Rough Sawn size | Net Size |

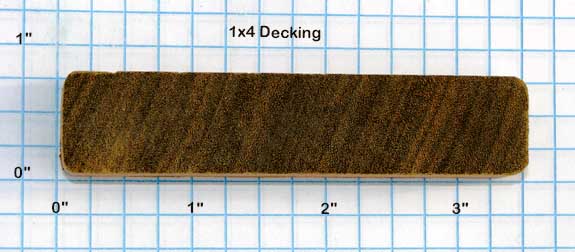

| 1 X 4 | 3/4″ x 3.5″ |

| 1 X 6 | 3/4″ x 5.5″ |

| 1 X 8 | 3/4″ x 7.25″ |

| 1 X 10 | 3/4″ x 9.25″ |

| 1 X 12 | 3/4″ x 11.25″ |

| 5/4 X 4 | 1 “x 3.5” |

| 5/4 X 6 | 1″ x 5.5″ |

| 5/4 X 8 | 1″ x 7.25″ |

| 5/4 X 10 | 1 “x 9.25” |

| 5/4 X 12 | 1″x 11.25″ |

| 2 X 2 | 1.5″ x 1.5″ |

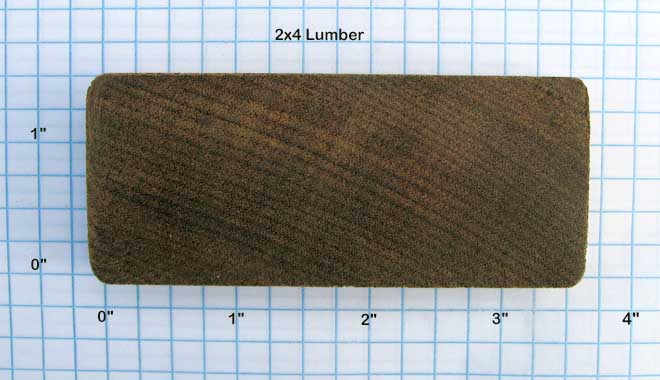

| 2 X 4 | 1.5″ x 3.5″ |

| 2 X 6 | 1.5″ x 5.5″ |

| 2 X 8 | 1.5″ x 7.25″ |

| 2 X 10 | 1.5″ x 9.25″ |

| 2 X 12 | 1.5″ x 11.25″ |

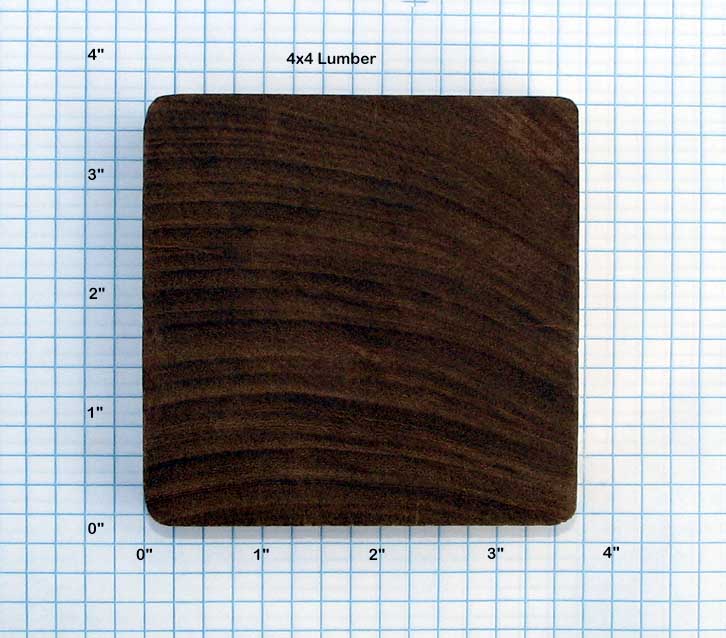

| 4 X 4 | 3.5″ x 3.5″ |

| 6 X 6 | 5.5″ x 5.5″ |

Ipe railing and Handrails, common code requirements

Handrails and railings play a critical role in providing safety and support for users of stairs, balconies, decks, and other elevated surfaces. These components are not only functional but also contribute to the aesthetics of a space, enhancing its overall design.

Common code requirements for handrails and railings are established to ensure compliance with safety standards and building regulations. These requirements typically specify dimensions, materials, spacing, and installation methods to minimize the risk of accidents and injuries.

Height regulations are a primary consideration, with handrails typically required to be installed at a specific height above the walking surface to provide adequate support and prevent falls. Additionally, regulations dictate the minimum and maximum spacing between balusters or spindles to prevent entrapment and ensure structural integrity.

What you need to know:

Usually, deck railings are required for any deck higher than 30 inches above the ground, and for stairs with five or more steps. Local building codes are quite specific about this so check the code in your area for the specification. The height of a deck railing is usually between 30 and 40 inches, but again this can be subject to various restrictions.

Here are some typical specs for deck railings so you know what to expect. Be sure to verify with the building codes in your area:

- railing height: 36″ to 42″

- baluster spacing: 3 1/2″ to 4″ – the inspector will check with a ball

- post-to-baluster spacing: 3 1/2″ to 4″

- deck-to-bottom rail spacing: 2″ to 4″

- no footholds – kids should not be able to climb over them

- They need to meet certain strength ratings, typically,if a 300-lb man were to fall against the deck railing, it should not move more than 1″

- Pool deck railings can be different in every area and must be verified

- You may be surprised to find that there is no appeal process in place. You might consider submitting drawings for approval ahead of time when you plan on doing something different than the norm

Home Owner’s associations is different again. Do not be surprised to see “No building whatsoever without approval by the association.”

There are historic districts in most cities and a committee rules these. These areas are far better looking than the norm because the architects are challenged to do their best work.

Types of IPE Deck Railings

There are several types of Ipe railings, each offering distinct styles and functionalities to complement various architectural designs and personal preferences:

Traditional Wooden Railings:

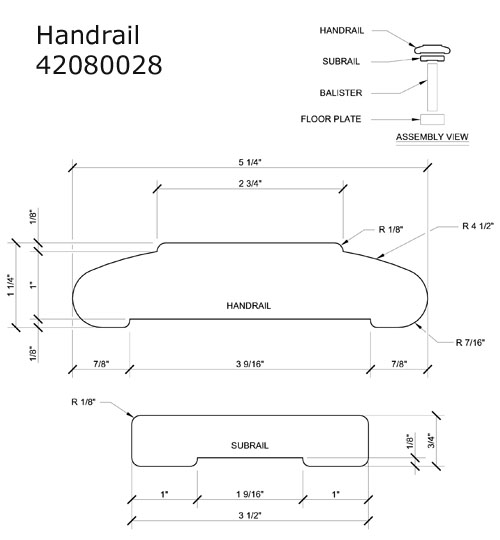

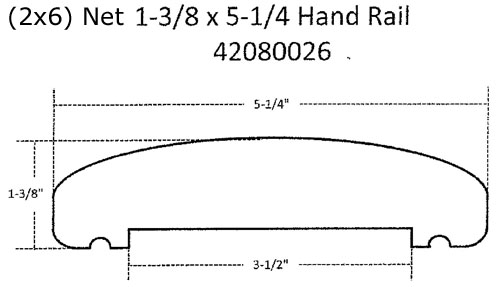

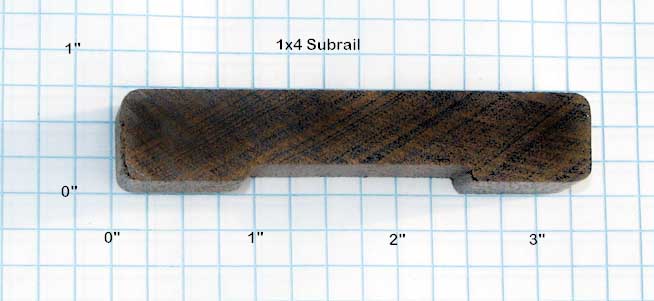

These railings are crafted from solid Ipe wood, providing a classic and timeless look. They can be customized with different profiles and baluster styles to match the overall aesthetic of the deck. The ABS 2×6 Ipe or custom milled 2×6 #28 are very popular. The 2×4 bottom rail and 2×2 balusters (pickets) are commonly used in conjunction.

Metal and Ipe Combinations:

Combining Ipe railing wood with metal elements such as wrought iron, aluminum, or stainless steel creates a modern and stylish railing design. This combination offers durability and visual interest, adding a contemporary touch to the deck. The ABS 2×6 ipe or custom milled #28 are the most popular with metal balusters and pickets.

Cable Railings:

Cable railings utilize stainless steel cables tensioned between Ipe wood posts or frames, creating a sleek and minimalist appearance. This type of railing provides unobstructed views and a sense of openness while maintaining safety and stability. The Ipe 4×4 are used as posts and ABS carries Deckwise Cable Railing systems.

Ultimately, the choice of Ipe deck railing depends on factors such as architectural style, desired aesthetic, budget, and functional requirements. By exploring the various types of Ipe railings available, homeowners and designers can find the perfect solution to enhance their outdoor living space.

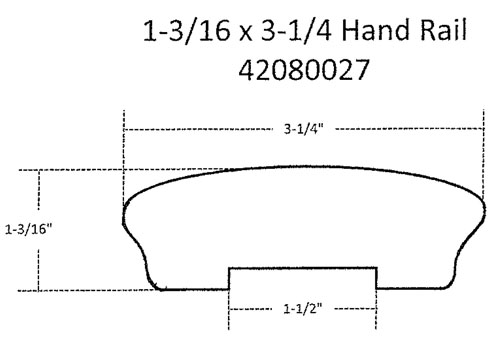

42080027 Handrail is special order

42080027 Handrail is special order

Ipe Handrail Example

- ABS Wood has various handrail systems. You can mix and match to get the style or look you desire.

- You can use all wood or use wood handrail atop Fortress Railing products.

- Just call and talk to any customer service representative for more information.