IPE WOOD PROBLEMS THAT CAN HAPPEN AND HOW TO ADDRESS THEM AKA DECKING WISDOM

Common Ipe Wood Problems That Can Happen—And How to Solve Them

At ABS Wood, we’ve spent years helping customers build long-lasting, beautiful decks using the finest Brazilian hardwoods like Ipe, Cumaru, Garapa, and Tigerwood. But even with premium materials, every decking project can come with a few hiccups. Whether you’re a homeowner building your dream backyard or a contractor on a tight schedule, being prepared for challenges will help you avoid delays, costly mistakes, and frustration.

Below, we dive into the most common ipe wood problems—some are technical, others are misunderstandings—and how to deal with each one like a pro.

- Last-Minute Orders: Planning Beats Panic

One of the most common ipe wood problems we see is customers waiting until the very last minute to place their order. After months of research, layout planning, and budgeting, many expect their Ipe hardwood decking to arrive immediately.

Here’s the truth: Brazilian hardwoods are typically special order items, and even if your chosen material is in stock, it still takes time to process and ship.

What to do:

- For in-stock items, plan for at least 2–3 weeks from order to delivery.

- If you need custom milling (e.g., grooves or special profiles), add another week.

- Always buffer your project timeline to avoid job site shutdowns due to delays.

- Wood Damaged During Shipping: Don’t Panic, Take Pictures

Though rare, shipping damage is another one of the occasional ipe wood problems that can catch you off guard. Given the weight and volume of a shipment, sometimes a crate may break in transit.

What to do:

- Take clear photos of the damaged wood immediately—while it’s still on the truck.

- Do not sign the Proof of Delivery (POD) until you’ve inspected the boards.

- If boards are damaged, mark it on the POD, and get a copy or snap a photo of it.

- Most scratches or dents are superficial. Ipe, Cumaru, and other Brazilian hardwoods are so hard that imperfections are often only surface-level. Flip the board or sand it lightly with 80-grit paper and it’s as good as new.

At ABS Wood, we’re always here to assist you through the claim process if needed.

- Mis-cuts and Underordering: The Classic DIY Error

Homeowners often try to order the exact number of boards required, hoping to avoid waste. Unfortunately, that precision can lead to another common ipe wood problem: running short due to mis-measurements or cutting errors.

What to do:

- Always order 5%–10% extra material to cover mistakes and cuts.

- Contractors know this rule well and factor it into every order.

- Ordering a few extra boards may seem expensive upfront, but it saves you from high shipping costs for small follow-up orders and costly project delays.

And don’t worry—any leftover Ipe can be used to make stylish planters, benches, or garden features!

- Stacking Stick Marks: Don’t Be Fooled by Aesthetic Imperfections

Sometimes customers call us concerned about light-coloured stripes across their boards. These marks come from “stacking sticks”—wooden spacers used to separate boards for airflow during shipping from Brazil.

What to do:

- These marks are temporary and weather away naturally once the deck is exposed to sunlight and air.

- They do not affect the durability or strength of the decking.

These kinds of ipe wood problems are more perception than reality—but they’re still worth addressing for peace of mind.

- Garapa Black Marks: Iron Meets Wood

This is a specific issue related to Garapa decking, but it can happen with other hardwoods too. Black marks may appear when steel or iron touches the wood—especially during installation.

What to do:

- Avoid metal-on-wood contact wherever possible during installation.

- If unavoidable, clean the area thoroughly to remove residue.

- Use stainless steel tools and fasteners to minimise chemical reactions that cause discolouration.

- Tongue and Groove Decking: Special Requirements Apply

Tongue and Groove (T&G) decking gives you a smooth, floor-like finish with hidden screws. But it’s not suitable for every location.

Important tips:

- Only use T&G on covered porches.

- T&G decking is not waterproof—ventilation and drainage are essential.

- Never install T&G over a subfloor.

- Use adhesive to prevent movement, and don’t space boards too tightly—moisture causes expansion, which can lead to cupping or buckling.

This setup mimics indoor flooring, but outdoor conditions demand different rules.

- Buckling Decking: Avoid Tight Spacing

Buckling is another avoidable ipe wood problem. All wood expands and contracts with moisture and temperature changes. If your boards are jammed together, especially with T&G decking, they’ll warp or buckle over time.

What to do:

- Leave small gaps between boards during installation.

- Choose narrower planks if you’re concerned about seasonal movement.

- Slope the soil beneath the deck for drainage to reduce humidity build-up underneath.

- ACQ/MCQ Fasteners and Flashing: Chemistry Matters

If you’re installing decking on pressure-treated lumber (PT), fastener compatibility becomes crucial.

Installation tips:

- Use only MCQ-compliant flashing and stainless steel fasteners.

- Never use indoor fasteners outdoors—they’ll corrode quickly.

- Always pre-drill Brazilian hardwoods—they’re dense and resistant to standard nails or screws.

- After cutting, seal board ends with wax emulsion to prevent end checking.

- Wood Imperfections: Nature’s Fingerprint

Another perception-based concern is the natural variation found in hardwoods. Many customers expect perfection—but the unique grain, colour variation, or occasional knot is part of the charm.

What to do:

- Understand that wood is a natural material, not a manufactured product.

- Variations in grain and colour add character and visual interest.

- Brazilian woods like Ipe and Cumaru offer stunning patterns, especially in long planks.

- Finishing—or Not: It’s Up to You

One of the great things about Ipe and other Brazilian hardwoods is that you don’t need to finish them. They’re naturally rot- and insect-resistant.

Options:

- If left untreated, the wood will weather to a beautiful silvery-grey patina.

- If you want to preserve the rich brown colour, use a UV-blocking sealer like Penofin.

- Either way, your deck will remain durable and stunning.

- Splinters Happen—Wear Gloves

Yes, even premium wood like Ipe can splinter. It’s one of those ipe wood problems that’s universal across all hardwoods.

What to do:

- Wear gloves when handling.

- Don’t slide across your deck or walk barefoot until it’s fully installed and sanded if needed.

1. What are the most common Ipe wood problems, and how can I avoid delivery and scheduling delays?

The most common Ipe issues relate less to the wood itself and more to logistics and installation preparation.

- Lead times & availability: Ipe is a specialty hardwood, and even when boards are in stock, delivery usually takes 2–3 weeks. Custom milling (such as grooves for hidden fasteners) may add another week.

Tip: Place your order early—don’t wait until the last minute. Build lead time into your project schedule.

- Shipping & damage claims: While rare, crates can be damaged during transit. If this happens, it must be noted on the delivery slip.

Tip: Always inspect your shipment before signing. Take photos of any damage and contact ABS Wood right away for assistance with claims.

- Ordering mistakes & shortages: Mis-measurements or unexpected cutting errors can slow projects.

Tip: Order 5–10% extra material to cover mistakes or waste—it’s cheaper and faster than reordering later.

- Scheduling delays with installers: Because of Ipe’s density, installation requires pre-drilling, stainless steel fasteners, and sometimes grooving. Delays happen if installers aren’t ready for this.

Tip: Confirm that your contractor has experience with Ipe and the right tools before your order arrives.

In short: Most “Ipe problems” can be avoided with good planning, order early, inspect deliveries, allow extra material, and work with experienced installers.

2. Can mis-cuts and underordering be one of the Ipe wood problems I need to watch for, and what's the best way to prevent it?

Yes — mis-cuts and underordering are among the most common Ipe wood problems homeowners and contractors face. Because Ipe is dense and requires pre-drilling, mistakes happen more easily than with softer woods. If you don’t order enough material, even a few mis-cuts can cause costly delays.

- Order 5–10% extra material to cover cutting errors, waste, and on-site adjustments.

- Measure twice, cut once — precision matters with hardwood.

- Use carbide-tipped blades and drill bits designed for dense tropical lumber to reduce mistakes.

- Work with experienced installers who know how to handle Ipe properly.

In short: Ordering a little extra upfront is the easiest way to avoid project delays and frustration from mis-cuts or shortages

3. Is splintering a typical Ipe wood problem, and what safety steps should I take during handling?

Yes. Splintering can occur with Ipe, especially during cutting, drilling, or when boards are freshly milled. Because Ipe is extremely dense and hard, splinters can be sharper and more painful than those from softer woods. While splintering is not excessive, it’s something to watch for during installation and handling.

- Always wear gloves when moving or installing Ipe boards.

- Use protective eyewear and a dust mask when cutting or drilling, as the fine dust can irritate skin and lungs.

- Sand exposed edges and ends to reduce sharpness before installation.

- Avoid walking barefoot on newly installed boards until the surface has been cleaned and settled.

- Seal cut ends with an end-grain sealer to reduce checking and rough edges.

In short: Splintering is a normal issue with hardwoods like Ipe, but with proper handling and protective gear, it’s easy to avoid injuries and keep your project safe.

4. How do I prevent Ipe wood problems related to fastener reactions, like black stains from iron, and board movement?

Fastener choice and installation methods play a huge role in the long-term performance of Ipe decking. Two common issues are staining from metal reactions and unwanted board movement.

- Only use stainless steel screws, nails, and hardware — never iron or standard steel.

- Avoid placing tools or steel fragments on the boards during installation.

- Clean any metal dust or residue right away to stop chemical staining.

- Leave proper spacing between boards for natural expansion and contraction.

- Use hidden clip systems or face-screws with stainless steel fasteners for secure, flexible installation.

- Pre-drill holes to prevent splitting and ensure a tight fit.

- Make sure the substructure has good ventilation and drainage so moisture doesn’t cause swelling.

Seal all cut ends with an end-grain sealer to reduce cracking.

5. What causes Ipe wood problems such as stacking stick marks, and do they affect deck quality?

Stacking stick marks (sometimes called “sticker marks”) are light-colored strIpes that can appear on Ipe boards when they’re separated by wooden spacers during shipping and storage. These spacers allow air circulation and prevent warping, but the areas under the sticks receive less sunlight and air exposure, creating temporary discoloration.

- Stacking stick marks are only surface-level and do not affect the strength, durability, or performance of your decking.

- Once the boards are installed and exposed to sunlight, rain, and air circulation, the marks naturally fade and even out over time.

If you prefer faster results, a light sanding or application of a UV oil finish can help blend the color more quickly

Customer Support

Get the 5-star support you deserve — because your business matters to us!

Request a Quote Now

Ipe Decking Prices

Get the best Ipe Decking at unbeatable prices — delivered directly to you!

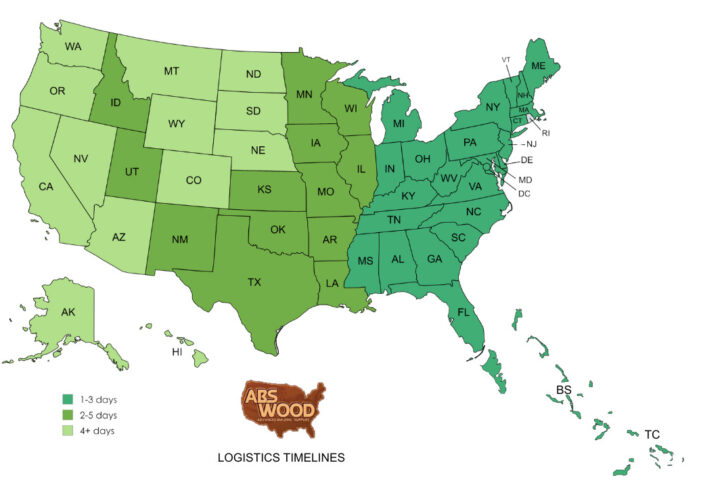

IPE Pricing InfoShipping Information

Shipping Locations

| Area | Transit Time |

| Northeast States | 1 to 3 days |

| Southern States | 1 to 3 days |

| Midwest States | 2 to 5 days |

| West coast | 1 to 3 days |

| European Countries | 3 weeks |

Calculators

Coverage Area (SF)

Calculation Results

| Area (SF) | 0.00 |

| Waste (SF) 10% | 0.00 |

| Total SF | 0.00 |

Square Feet to Linear Feet

Result

Linear Feet: 0.00

Board Feet Calculator

Calculation Results

| Board Feet (BF) | 0.00 |

| Linear Feet (LF) | 0.00 |

| Square Feet (SF) | 0.00 |