IPE WOOD DECKING INSTALLATION

Installation Questions for Ipe wood Decking

and all Brazilian Hardwoods

Complete Guide to Ipe Wood Decking Installation: Everything You Need to Know

When you’re investing in an outdoor living space, you want materials that combine beauty, longevity, and strength. That’s where ipe wood decking stands out. At ABS Wood, we’ve spent years helping homeowners and builders across the U.S. bring their dream decks to life using only the finest Brazilian hardwoods — and ipe is our most popular choice. Whether you’re working on a brazilian wood deck by the beach or in your backyard, here’s everything you need to know about proper ipe decking installation.

Why Choose Ipe Wood Decking?

Ipe wood decking is known for its incredible hardness, natural resistance to decay and insects, and elegant appearance. Its tight grain and rich brown tones give it a luxurious feel while standing up to the harshest weather conditions. Unlike softer woods, Ipe doesn’t splinter easily and can last over 40 years with minimal upkeep. It’s a clear favourite for homeowners who want performance without compromising aesthetics.

Storage and Handling: Let It Acclimate

One of the most important aspects of ipe decking installation begins before you even start building. At ABS Wood, we supply Ipe that’s partially air-dried. However, before installation, it’s crucial to store the boards out of direct sunlight and allow them to acclimate to the local humidity and climate.

Proper acclimation helps minimise future movement like shrinkage or cupping. Good air circulation around the boards — especially underneath them once installed — is essential. For ventilation and airflow, leave a 1/16″ gap between boards during installation.

Ideal Spacing and Board Gaps

Brazilian wood decks, including Ipe, will naturally shrink slightly as they dry and season. On average, expect a 1/16″ reduction on 4” wide boards and up to 1/8″ on 6” wide boards. If you’re installing during colder months (below 40°F), use a tighter spacing of 1/16” to account for later shrinkage. Always use a spacer tool for even gaps, especially when doing a hidden fastener installation.

Understanding the Substructure

Just like any wood decking, a solid substructure is vital. Use pressure-treated lumber for your joists and make sure they’re spaced no more than 16” apart. This is the maximum recommended span for 1×6 ipe wood decking.

When planning your ipe decking installation, especially in areas with high humidity like Florida or Louisiana, always consult local building codes or a structural engineer. Certain states may have specific regulations, particularly for dock or elevated installations.

Cutting and Drilling Ipe

Working with Ipe is unlike working with pine or cedar. Due to its density, it requires specialised tools. Use high-quality carbide-tipped saw blades to achieve clean, smooth cuts. For fastening, always pre-drill pilot holes and use countersinks — this prevents splitting and ensures a flush, professional finish.

At ABS Wood, we recommend using a Smart-Bit or similar tool that drills and countersinks simultaneously to save time and effort.

Fastening: What to Use and What to Avoid

Fastening is one of the most crucial aspects of a successful ipe decking installation. Stainless steel screws are the gold standard — they don’t rust, stain, or cause chemical reactions with the wood. Galvanised or coated screws may be cheaper but tend to corrode faster and can leave unsightly marks over time.

We suggest using Headcote or DeckWise stainless steel screws, with a minimum length of 2.5 inches. These have smaller heads, making them less visible and more aesthetically pleasing.

Hidden Fastener Systems

For homeowners who want a seamless look, hidden fasteners are an excellent choice. ABS Wood carries grooved boards that work perfectly with hidden systems like Ipe Clip Extreme. These clips lock into the grooves, creating a smooth surface with no visible screws — all while providing over 1,000 lbs of holding power.

What sets our system apart? It installs from the top of the deck, so you don’t have to crawl underneath or twist into awkward positions. This feature alone makes it a favourite for both professionals and DIYers.

Don’t Forget End Sealing

Whenever you cut a board, seal the end grain immediately with a wax-based end sealer like Ipe Seal. This prevents “end checking,” which is the development of small cracks due to moisture imbalance. At ABS Wood, all our boards come pre-sealed at the mill, but any field cuts should be treated right away for optimal performance.

Deck Design Options: Covered vs. Uncovered

When it comes to planning your brazilian wood deck, consider how you’ll use the space:

Covered Decks

- Protection from weather: Shield your deck from rain, sun, and snow.

- Increased usability: Great for entertaining and outdoor kitchens.

- Less maintenance: Reduces fading and wear.

- Higher home value: Adds premium living space to your property.

Uncovered Decks

- Natural experience: Perfect for sunbathing or stargazing.

- Lower cost: Fewer materials and simpler construction.

- Greater versatility: Easier for gardening and barbecues.

Both options are ideal for ipe wood decking — it just depends on your lifestyle.

Installation Steps: Building Your Ipe Deck

Here’s a quick walk-through of the ipe decking installation process:

- Prepare the substructure: Ensure it’s level and stable with joists spaced 16″ apart.

- Acclimate the boards: Leave them on-site for a week, stored flat, covered with a tarp (but ends exposed for airflow).

- Ventilate properly: Include adequate ground-side airflow in your design to prevent cupping.

- Spacing: Maintain uniform gaps using spacers.

- Fastening: Pre-drill and countersink every screw; consider hidden fasteners for a cleaner finish.

- Seal ends: Use Ipe Seal after every cut.

- Finishing touches: Countersink all screws, check for any sharp edges, and clean up the surface.

Maintenance Tips for Long-Lasting Ipe Decks

Although Ipe is low maintenance, a bit of care goes a long way:

Cleaning

- Sweep regularly to remove dirt, leaves, and debris.

- Use a mild detergent or wood cleaner for periodic washes.

- Avoid high-pressure washers, as they can splinter the wood.

Oiling (Optional)

Ipe wood decking doesn’t require staining or sealing, but applying a UV-blocking oil finish can help preserve its original brown tones. If left untreated, the wood will age into a silvery patina — which some homeowners love. Either way, the performance remains unchanged.

Regular Inspections

- Check for loose boards or screws.

- Look for dirt buildup around the base and trim vegetation.

- Inspect joists and ledgers for structural soundness.

Insect Resistance: A Natural Bonus

All of our brazilian wood deck materials — including Ipe — are naturally resistant to termites, pine beetles, and even marine borers. This makes them ideal not just for backyards, but also for coastal decks and docks.

1. Do ABS Wood offer customer support or assistance if I encounter any challenges during the Ipe decking installation process?

ABS Wood has experienced builders for all customer facing positions. We have been on the jobsite. We have built it. If a customer has any questions, we are available to help. If we do not know the answers, we have a depth of resources to find out. Whatever happens ABS Wood is here to help.

2. What type of fasteners are recommended for Ipe decking installation to ensure a secure and long-lasting result?

Deck Fasteners tend to fall into 2 categories; hidden and face screws. Conventional Face screws are commonly used. With Brazilian Hardwoods only use Stainless Steel. The MCQ Compliant screws will cause tannin weep. This will look like rust stains. Only stainless prevents this occurrence. If a customer desires the hidden look, then Ipe Clip Extreme is the fastener of choice. The Ipe Clip Extreme has stronger holding power than most any other hidden faster. In addition, it keeps the boards straight as the deck ages. Other clips allow the boards to “slip out” from under the fasteners. Ipe Clip Extreme holds the boards in place preventing slip out.

3. What are the specific benefits of Brazilian wood decking from ABS Wood compared to other decking materials on the market?

Brazilian woods like Ipe, will last for decades. It does not rot, termites and pine beetles will not attack it, it will not decay. The labour to install a deck in comparable no matter what decking you use. However, unlike Pine, Cedar or other common deck materials, Brazilians will last. This will stretch out your investment for a much longer time.

Customer Support

Get the 5-star support you deserve — because your business matters to us!

Request a Quote Now

Ipe Decking Prices

Get the best Ipe Decking at unbeatable prices — delivered directly to you!

IPE Pricing InfoShipping Information

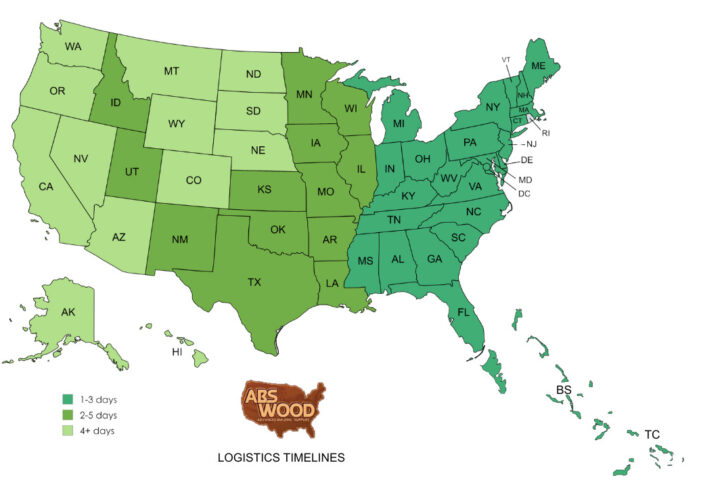

Shipping Locations

| Area | Transit Time |

| Northeast States | 1 to 3 days |

| Southern States | 1 to 3 days |

| Midwest States | 2 to 5 days |

| West coast | 1 to 3 days |

| European Countries | 3 weeks |

Calculators

Coverage Area (SF)

Calculation Results

| Area (SF) | 0.00 |

| Waste (SF) 10% | 0.00 |

| Total SF | 0.00 |

Square Feet to Linear Feet

Result

Linear Feet: 0.00

Board Feet Calculator

Calculation Results

| Board Feet (BF) | 0.00 |

| Linear Feet (LF) | 0.00 |

| Square Feet (SF) | 0.00 |