IPE RAILING SPECIFICATIONS

Understanding Ipe Decking and Ipe Railing: What Every Homeowner Should Know

At ABS Wood, we pride ourselves on offering premium Brazilian hardwoods like Ipe, Cumaru, and Garapa that deliver lasting beauty and exceptional performance. But choosing the right decking and ipe railing isn’t just about picking what looks good—it’s also about understanding the technical details and anticipating common issues. Here’s a simplified, no-fluff guide to help you understand the key terms, common challenges, and essential information when working with Ipe hardwoods.

Ipe Decking: Dimensions and Specifications

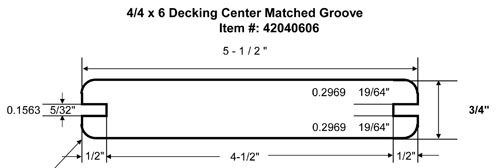

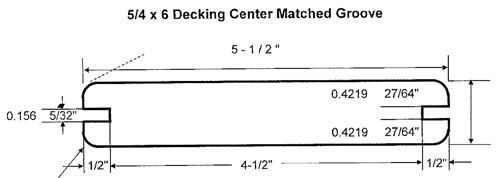

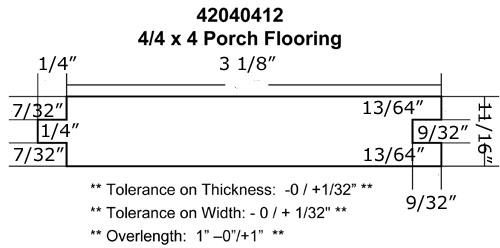

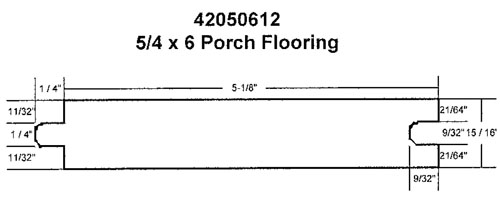

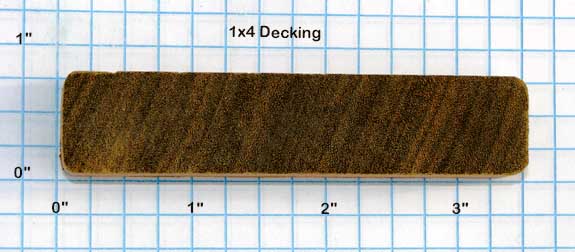

When it comes to Ipe decking: dimensions and specifications, things can get confusing. For starters, when people say “board feet,” they often really mean linear feet, which is how most orders are placed in the decking world. Linear feet measure length, while board feet calculate volume. Nominal sizes like 1×6 are commonly used for marketing, but the actual (or rough) size can differ once the wood is processed. For example, a ¾” x 5 ½” board might start as a rough 1” x 6”. This matters for planning, especially when matching cuts or calculating coverage. If you see S4S E4E, it means the boards are surfaced on all four sides with eased edges—ready to use, safer to handle, and less likely to splinter. Grooved boards are machined on both sides to fit clips like the Ipe Clip Extreme, which helps achieve a clean, screw-free surface. Rough sawn lumber, on the other hand, is unprocessed wood with a coarse finish and saw marks. While it’s common in bulk construction like Apitong truck decking, it’s not typically used for high-end residential decks. Measurement-wise:

- Cubic meters are for bulk timber orders (great for B2B).

- Board feet are still standard in the lumber industry.

- Linear feet is what you’ll likely be using for your deck order.

Common Problems (and How to Avoid Them)

Let’s face it—even the best materials can present a few challenges. Some of the most common Ipe wood problems include:

- Late ordering: Always plan at least 2–3 weeks ahead to allow for delivery and milling.

- Shipping damage: Inspect your shipment on arrival and take pictures. Superficial damage can usually be sanded out.

- Underordering: Always order 5–10% extra to account for miscuts or mistakes.

- Stacking marks: Light marks caused by shipping spacers fade with sunlight.

- Garapa discolouration: Metal contact with wood can leave black marks—use stainless steel tools and fasteners to avoid this.

- Buckling decks: Wood expands! Leave space between boards, especially with tongue and groove applications.

- Finishing: Want that deep brown colour? Use a UV sealer. Prefer a greyed-out look? Let nature do the work.

All About Ipe Railing If your deck is more than 30 inches off the ground or has stairs with five or more steps, you’ll need a code-compliant ipe railing system. These are not just safety features—they’re also design statements.

Key code specs:

- Railing height: 36″–42″

- Baluster spacing: 3.5″–4″

- Bottom spacing: 2″–4″

- No footholds (important for child safety)

- Strength rating: Must withstand 300-lb lateral force

- Pool railings and HOA rules may differ—always double-check local codes

Types of Ipe Railing

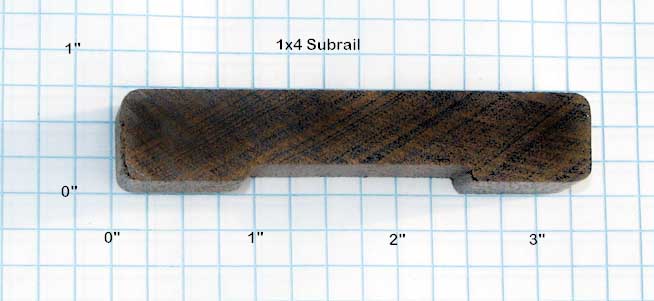

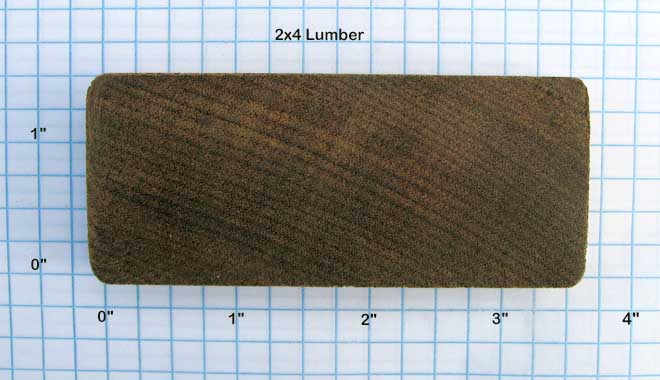

- Traditional Wooden Railings: Solid ipe railing components (like ABS’s 2×6 and 2×4 rails) offer a warm, timeless look. Paired with 2×2 balusters, they’re a favourite for rustic or classic deck designs.

- Metal and Ipe Combos: Modern and stylish, these railings blend Ipe with aluminium or stainless steel. The 2×6 ipe railing with metal balusters is a popular combo that balances elegance and durability.

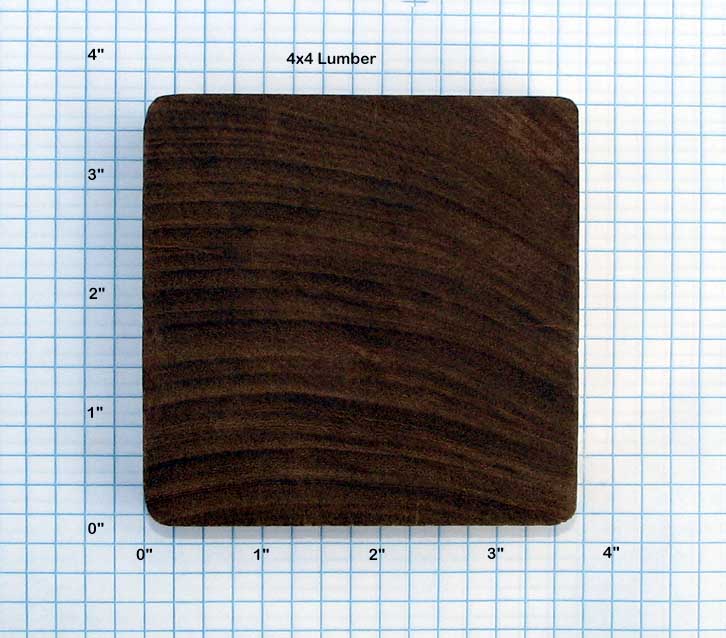

- Cable Railings: If you’re after sleek minimalism and unobstructed views, cable railings with Ipe 4×4 posts are the way to go. ABS Wood carries Deckwise Cable Railing Systems, perfect for a high-end look.

Each style of ipe railing offers unique benefits. Whether you prefer traditional charm or contemporary minimalism, you’ll find a solution that complements your deck and meets safety standards. Each style of ipe railing offers unique benefits. Whether you prefer traditional charm or contemporary minimalism, you’ll find a solution that complements your deck and meets safety standards. Here’s what ABS Wood offers:

- Various handrail systems that can be mixed and matched to suit your desired style or look.

- All-wood options for a classic, natural finish.

- Wood handrails atop Fortress Railing products for a modern, durable combination.

Personalised support — just call and speak to any of our customer service representatives for more information.

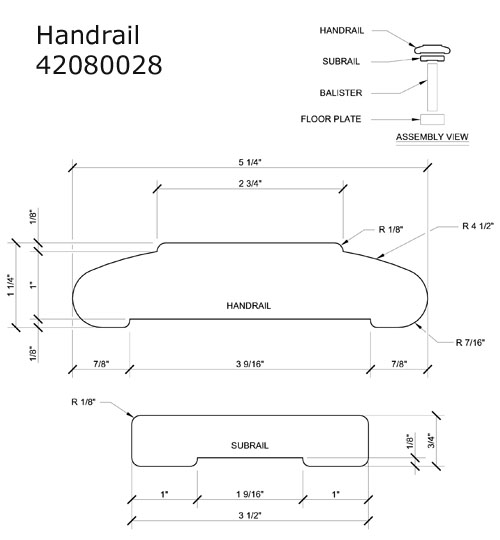

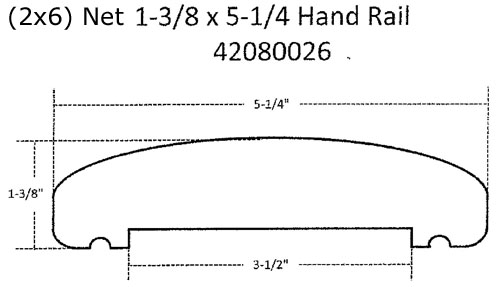

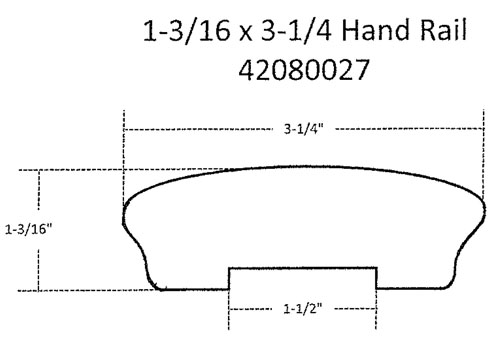

2x6 Handrail System

42080027 Handrail is special order

42080027 Handrail is special order

Ipe Handrail Example

1. What standard dimensions are important when planning an Ipe railing for a deck, and why does accuracy matter?

When building a deck railing with Ipe, a few key dimensions ensure safety, comfort, and compliance with building codes:

- Railing height: Typically 36″–42″ (check local code) — ensures fall protection and code compliance.

- Baluster spacing:5″–4″ apart — prevents children or pets from slipping through.

- Bottom gap:2″–4″ above the deck surface — allows drainage and airflow while meeting safety standards.

- Strength requirement: Railings must resist a 300 lb lateral force, making Ipe’s density and durability a reliable choice.

- Safety compliance: Incorrect spacing or height can lead to failed inspections and unsafe conditions.

- Aesthetics: Consistent spacing and accurate cuts keep the railing visually balanced and professional-looking.

- Material efficiency: Precise planning reduces waste and avoids under-ordering, which is especially important with premium hardwood like Ipe.

Ease of installation: Pre-drilled holes, hidden fasteners, and alignment all rely on accurate measurements to save time and labo

2. What types of Ipe railing styles does ABS Wood offer, and how do they affect dimension choices?

ABS Wood provides several railing style options in Ipe, each with its own look, functionality, and dimensional considerations:

1. All-Wood Railing Systems

1. All-Wood Railing Systems

- Description: Traditional design with Ipe top rails, posts, and balusters.

- Dimension impact:

- Top rails often use 2×4 or 2×6 Ipe boards.

- Balusters must be spaced 5″–4″ apart to meet code.

- Posts (typically 4×4) must be securely anchored for strength.

- Best for: A classic, all-natural hardwood appearance.

2. Mixed-Material Railings (Ipe + Metal or Glass)

2. Mixed-Material Railings (Ipe + Metal or Glass)

- Description: Combines Ipe top rails with metal, aluminum, or glass panels for a modern aesthetic.

- Dimension impact:

- Ipe top rails usually follow 36″–42″ height requirements.

- Spacing depends on the type of infill (metal rods, glass, etc.), often requiring fewer balusters.

- Best for: Contemporary designs where Ipe adds warmth against sleek materials.

3. Cable Railing Systems

3. Cable Railing Systems

- Description: Ipe posts and top rails paired with stainless steel cables for an open, streamlined look.

- Dimension impact:

- Posts are typically 4×4 Ipe, placed closer together than with balusters to keep cable tension.

- Cable spacing must follow the 4″ safety rule (no opening wider than 4″).

- Top rail dimensions (often 2×6) provide the needed strength for cable tension.

- Best for: Decks where preserving views and airflow is a priority.

3. Can I use specified Ipe railing components for area compliance beyond safety—like integrated surface shelving?

Yes. Ipe railing components can do more than just meet safety code requirements—they can also be designed for added functionality and style. While railings must always comply with height, spacing, and strength standards, the robust nature of Ipe allows creative integrations such as:

- A wider top rail (often a 2×6 or 2×8 Ipe board) can double as a functional shelf for drinks, plants, or décor.

- This must still sit at the required 36″–42″ railing height to remain compliant.

- Ipe’s density makes it ideal for smooth, flat top rails that act as ledges without losing structural integrity.

- Works especially well in cable railing or mixed-material systems where the top rail is the main wood element.

- Any modification must still resist the 300 lb lateral load requirement for safety.

- Baluster or cable spacing rules (no openings larger than 4″) must remain unchanged, even if shelving is added.

Wider components should be factored into your material planning, as they can affect both aesthetics and cost.

4. Are there dimensional considerations when combining Ipe railing with hidden fasteners or accessories?

Yes. When integrating hidden fasteners or accessories into an Ipe railing system, you’ll want to account for both the board dimensions and how they interact with railing hardware:

- Grooved vs. Square-Edge Boards

- Hidden fasteners like Ipe Clips require pre-grooved boards or on-site routing to create grooves.

- This slightly reduces the usable board width, so dimensions must be measured carefully when planning railing runs.

- Top Rail Thickness

- If using hidden fasteners for decking that connects to railing posts, ensure the top rail (often 2×4 or 2×6) has adequate thickness for screws without splitting.

- Carbide-tipped drill bits and pre-drilling are recommended for precision.

- Post Dimensions & Accessories

- Ipe 4×4 posts must allow for the secure attachment of hidden hardware, brackets, or cable tensioners.

- Posts placed too far apart may reduce structural integrity, especially with cable railing systems.

- Clearances & Aesthetics

- Hidden fasteners are designed to maintain a seamless look, but you must allow proper spacing (typically 1/16″–1/8″) between boards to accommodate natural movement of Ipe.

Accessories like lighting, drink rails, or cap boards may require wider or thicker components to remain flush and visually balanced.

5. Do local code requirements for Ipe railing vary significantly, and how should I plan accordingly?

Yes, railing code requirements can vary depending on your location, and it’s essential to plan with both safety and compliance in mind. While Ipe itself is strong and durable enough to meet or exceed most standards, the exact dimensions and specifications required may differ.

- Railing height: Typically 36″ for residential decks, 42″ for commercial or multifamily structures.

- Baluster spacing: No gap larger than 4″ to prevent children from passing through.

- Bottom rail gap:2″–4″ above the deck surface for drainage and safety.

- Strength requirement: Railings must withstand a 300 lb lateral load.

- Some areas enforce stricter requirements for decks near pools, lakes, or coastal zones.

- Wind and hurricane-prone regions may require closer post spacing and reinforced fasteners.

- HOAs (Homeowner Associations) may have aesthetic or material restrictions, even if Ipe complies structurally.

- Check your jurisdiction’s building code before finalizing railing dimensions.

- Confirm with your contractor that your railing design (height, spacing, and fastener choice) aligns with local regulations.

- Use Ipe components sized appropriately (e.g., 4×4 posts, 2×4 or 2×6 top rails) to ensure strength while staying code-compliant.

- Plan for inspections—accuracy matters not just for safety but also to avoid costly rework.

Customer Support

Get the 5-star support you deserve — because your business matters to us!

Request a Quote Now

Ipe Decking Prices

Get the best Ipe Decking at unbeatable prices — delivered directly to you!

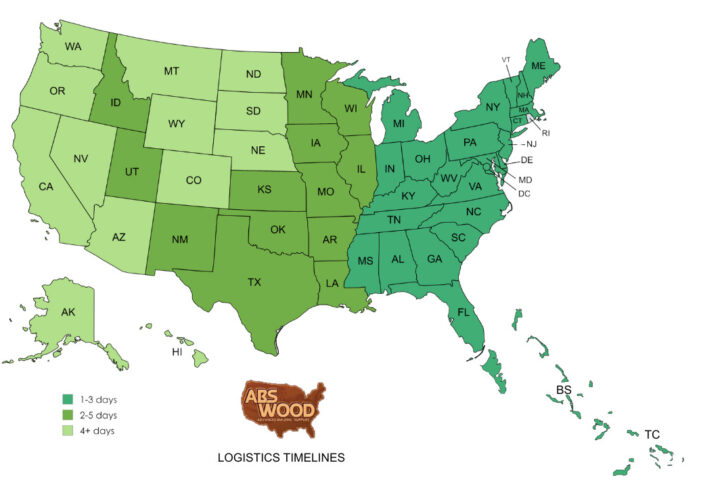

IPE Pricing InfoShipping Information

Shipping Locations

| Area | Transit Time |

| Northeast States | 1 to 3 days |

| Southern States | 1 to 3 days |

| Midwest States | 2 to 5 days |

| West coast | 1 to 3 days |

| European Countries | 3 weeks |

Calculators

Coverage Area (SF)

Calculation Results

| Area (SF) | 0.00 |

| Waste (SF) 10% | 0.00 |

| Total SF | 0.00 |

Square Feet to Linear Feet

Result

Linear Feet: 0.00

Board Feet Calculator

Calculation Results

| Board Feet (BF) | 0.00 |

| Linear Feet (LF) | 0.00 |

| Square Feet (SF) | 0.00 |